Damper Aftermarket Solutions

In the world of energy, industrial dampers are vital in the control and isolation of flue gases in many industrial processes. Damper Technology Ltd (DTL) have an extensive range of operational damper equipment out in the field and therefore, understand the importance of being able to provide a knowledgeable and reliable Aftermarket Solutions Department.

This department caters for all your damper maintenance, refurbishment and upgrade requirements to extend the operational life and efficiency of this equipment and give you the confidence that your damper will operate effectively when called upon.

Our design and engineering services can re-evaluate the operating requirements of older systems and advise whether you can benefit from refurbishment or replacement of dampers, components or controls. We can assess your current operational conditions and requirements and offer new solutions to improve and/or extend the life of the equipment providing long terms savings.

Let DTL help you reduce your risk of failure and avoid costly downtime by having us as your Damper Service Partner. Get in touch today!

Want to talk to one of our experts? Request a callback.

Experienced in Damper Service

Together with all DTL projects, we also hold over 35 years of technical archives including GA drawings/manuals and parts lists for Becorit & Herweg, Long-Airdox Becorit and Effox UK. Allowing us to offer the same level of spares and maintenance solutions for new dampers and those that have been out in the field for a while.

Damper Aftermarket Services

Our Aftermarket Solutions Department offer the following services worldwide, both on and offshore:

- Damper Service Inspection

- Routine & Refurbishment Upgrade Work

- Life Extension/Warranties

- Outage Management

- Damper Commissioning

- Troubleshooting

- Repairs / Retrofit

- Spare Part Management

- Training Packages

Site Services

Our Aftermarket Site Services Team includes skilled and experienced engineers, fully qualified and certified for on and offshore operations. They provide service inspections, routine maintenance or extensive retrofit/overhaul of damper installations in any sector. This is backed up with office-based engineers, project managers and a full design team. All site work is supported by specific method statements and risk assessments.

Our experienced team will minimise any disruption to your operation and reassurance comes with a detailed service report. In addition, we provide recommendations, updated spare parts lists and an improvement plan on completion of all works.

Our activities are managed by our Quality Management System which conforms with the requirements of ISO 9001:2015.

Please contact us for more information.

Maintenance & Refurbishment

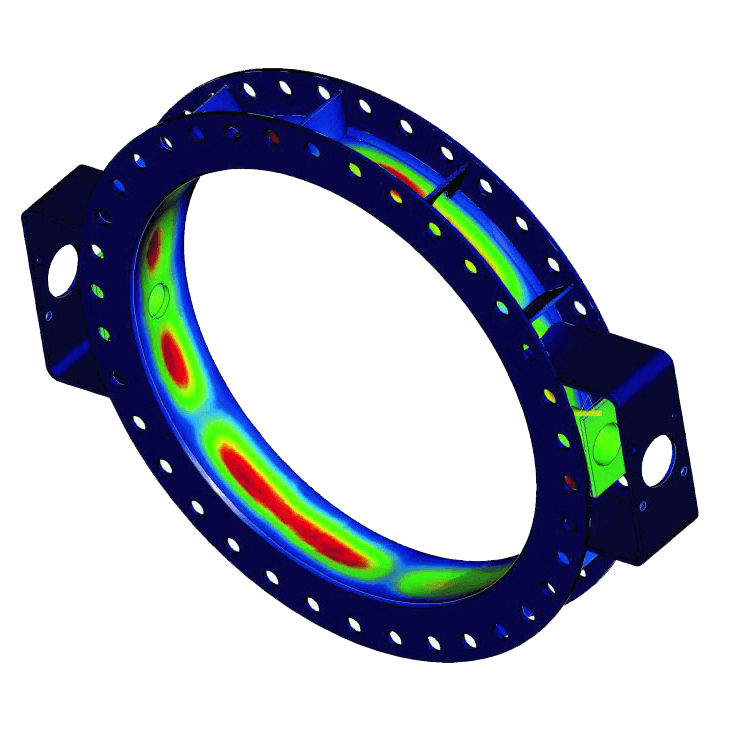

Damper failures can be foreseeable and preventable, the warning signs are usually there for the experienced engineer to see and proper management and maintenance of your damper systems can help to extend the lifetime of the equipment. We also understand that Dampers are often a small part of a large installation but they are critical to the performance, efficiency, stability and profitability of the process. With that in mind, regular maintenance by DTL personnel can provide you with peace of mind that your equipment is in a good operational condition that can be trusted.

You may have old equipment which has suffered the effects of time, or the weather. But it may be impractical to consider replacing the equipment for new either due to costs, or just access restrictions. DTL can provide a solution to refurbish or upgrade old or inefficient dampers in situ. We can offer site surveys to assess the equipment for feasibility and options for improvements. This is followed up by detailed engineering design works with full involvement of your team in the process, to ensure you get the solution your require, both operationally and technically suited to your existing systems and controls.

Please contact us for more information.

Training Services

DTL can provide complete Operation and damper maintenance training to help you get the best from your dampers and reduce the risk of failure due to lack of maintenance.

Our support packages are tailored to your actual damper product and controls, offering classroom and practical sessions, depending on the state of your installation.

Please contact us for more information.

Want to talk to one of our experts? Request a callback.

Advice & Info

Let DTL help you reduce your risk of failure and avoid costly downtime by having us as your Damper Service Partner.

Call us on +44 (0)1159324046

Or fill out the form on this page and we’ll get in touch shortly.