What are Industrial Dampers?

An industrial damper is a mechanical device used in various industrial applications to control the flow of gas or air within a duct or pipeline. Essentially a fabricated valve, dampers are designed to regulate the flow rate, pressure, or temperature of the fluid in a system. They can be manually operated or automated, depending on the specific requirements of the industrial process.

Primary Functions of a damper

Flow Control: Dampers can be adjusted to control the rate of flow of gases or air in a system. This is particularly important in processes where precise control over the flow is necessary for optimal performance.

Pressure Regulation: Dampers help regulate the pressure within a duct or pipeline by adjusting the cross-sectional area through which the fluid passes. This can therefore be crucial in maintaining a stable and controlled pressure in various industrial processes.

Temperature Regulation: In certain applications, dampers are used to control the temperature of the fluid by adjusting the flow. Accordingly, this is common in systems where maintaining a specific temperature is critical for operational efficiency or product quality.

Isolation: Dampers can act as isolation devices, shutting off the flow completely when needed. This is useful during maintenance or in emergency situations to isolate sections of a system.

Noise Control: Dampers can also be employed to mitigate noise generated by the flow of gases within a system. By adjusting the damper settings it can be possible to reduce the noise level in industrial environments.

Modes Of Damper Operation

Modulating

Blades modulate into any position between fully open and fully closed to regulate the flow of gas or air in the pipe or duct.

Isolating

Blades are either fully open or fully closed to allow or isolate the flow of gas or air in the pipe or duct.

Diverting

Using either a single flap or a combination of 2 butterfly (or louver) dampers, the flow from a common inlet is diverted to a choice of outlet ducts.

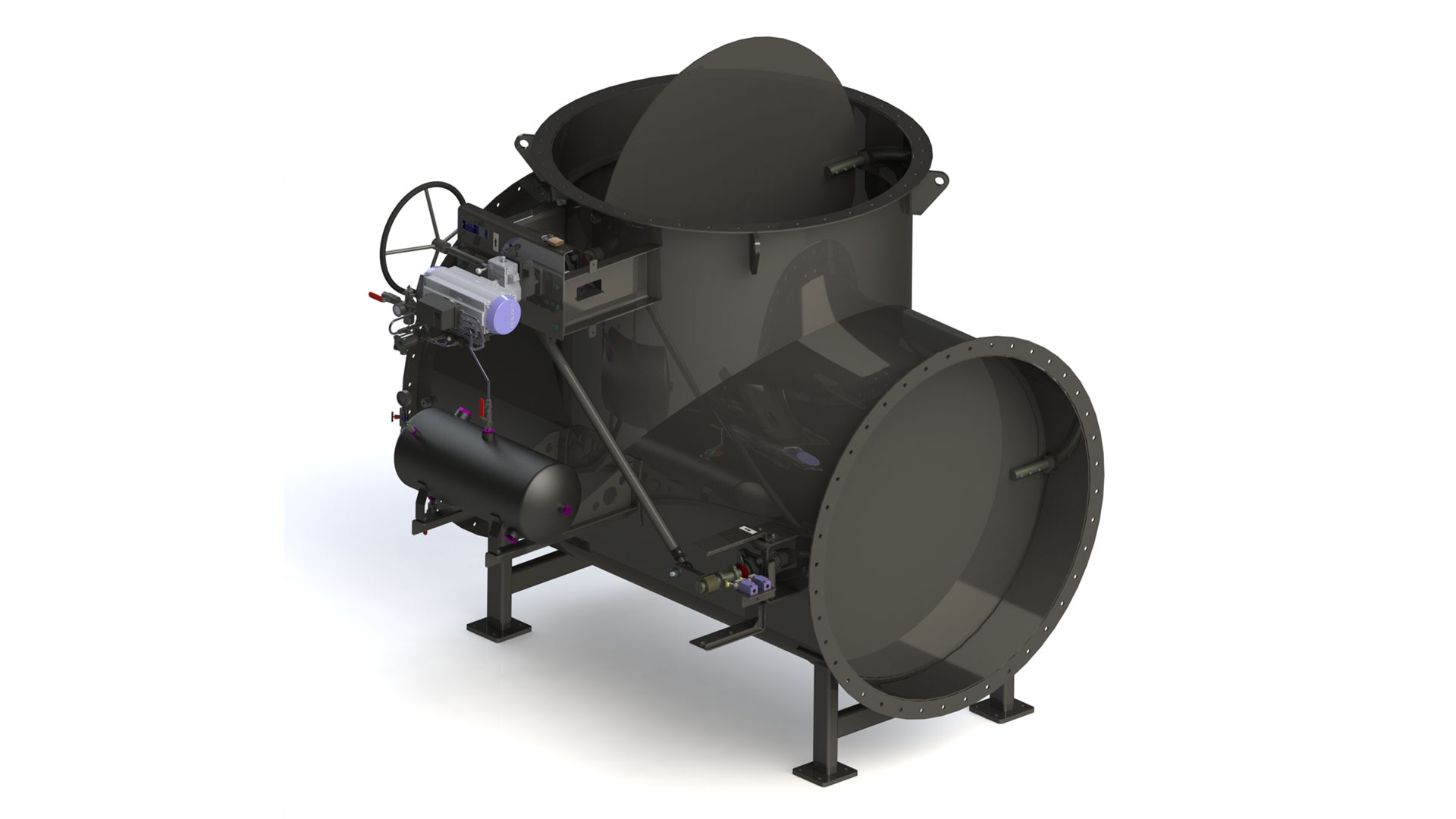

Basic Types Of Damper

Need help finding the right damper? Request a callback.

Some technical terms you might hear relating to dampers.

Fabricated

Unlike valves, dampers are generally designed and fabricated to order, according to your application.

Actuator

The device used to operate the damper. We provide pneumatic, electric, hydraulic or manual actuation.

Blade Seals

Damper blades are sometimes fitted with metallic seals to improve the sealing efficiency of the damper.

Blade Action

Parallel or Opposed, to describe the rotational relationship between adjacent damper blades.

Our product range of industrial air dampers covers a wide range of applications in many different industries because all of our dampers are designed and manufactured to meet your project specifications and process conditions including extreme high temperature applications, elevated pressures which may fall under the pressure equipment directive (PED), aggressive and / or hazardous environments such as offshore installations, and corrosive process applications such as scrubbers and sulphuric acid plants. And if your dampers form part of a structure we are able to design and manufacture to EN1090 Execution Class 3. Whatever your application, as a world renowned industrial dampers manufacturer we can tailor our products to meet your requirements.