Chemical plants offer an important service providing products we all use in our daily life.

Damper Technology have been successful in securing orders for Acid Resistant Butterfly Dampers for a major site upgrade at a Chemical plant specialising in methacrylate monomers in North Eastern England that provide the principal building block of acrylic which is used in products we rely on every day such as work surfaces, automotive parts, home appliances, baths, paint, lighting, retail displays and more.

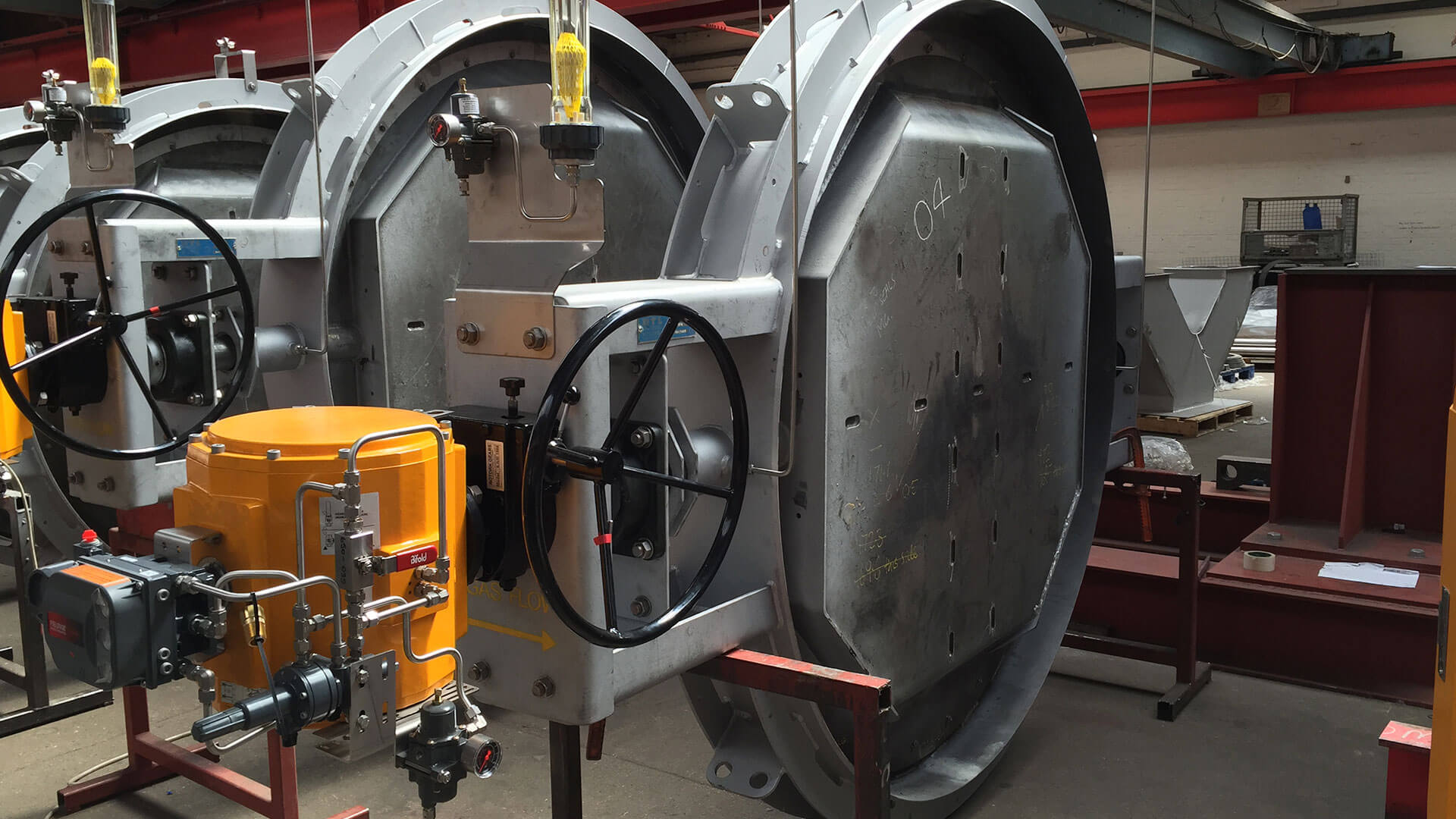

DTL Acid Process Dampers

The orders are for a mixture of Dampers manufactured in materials such as Super Duplex, Stainless steel 304H and a variety of Carbon Steel grades tailored especially to suit the exacting requirements of our customers process and ensuring that our Dampers shall remain corrosion free and reliable for many years.

DTL’s Acid Resistant Dampers offer not only resistance to Acid but also additionally provide excellent sealing efficiency across the duct to enable exacting process control and special shaft seals with purged lantern rings and labyrinth arrangement that guarantees Zero leakage of the process gas to the atmosphere, protecting both the environment and the safety of site personnel. Our gland arrangement requires very minimal maintenance to assist with your running costs. The fine process control coupled with zero leakage to atmosphere allow for a more efficient process which reduces expenditure and helps the environmental impact of this critical manufacturing process.