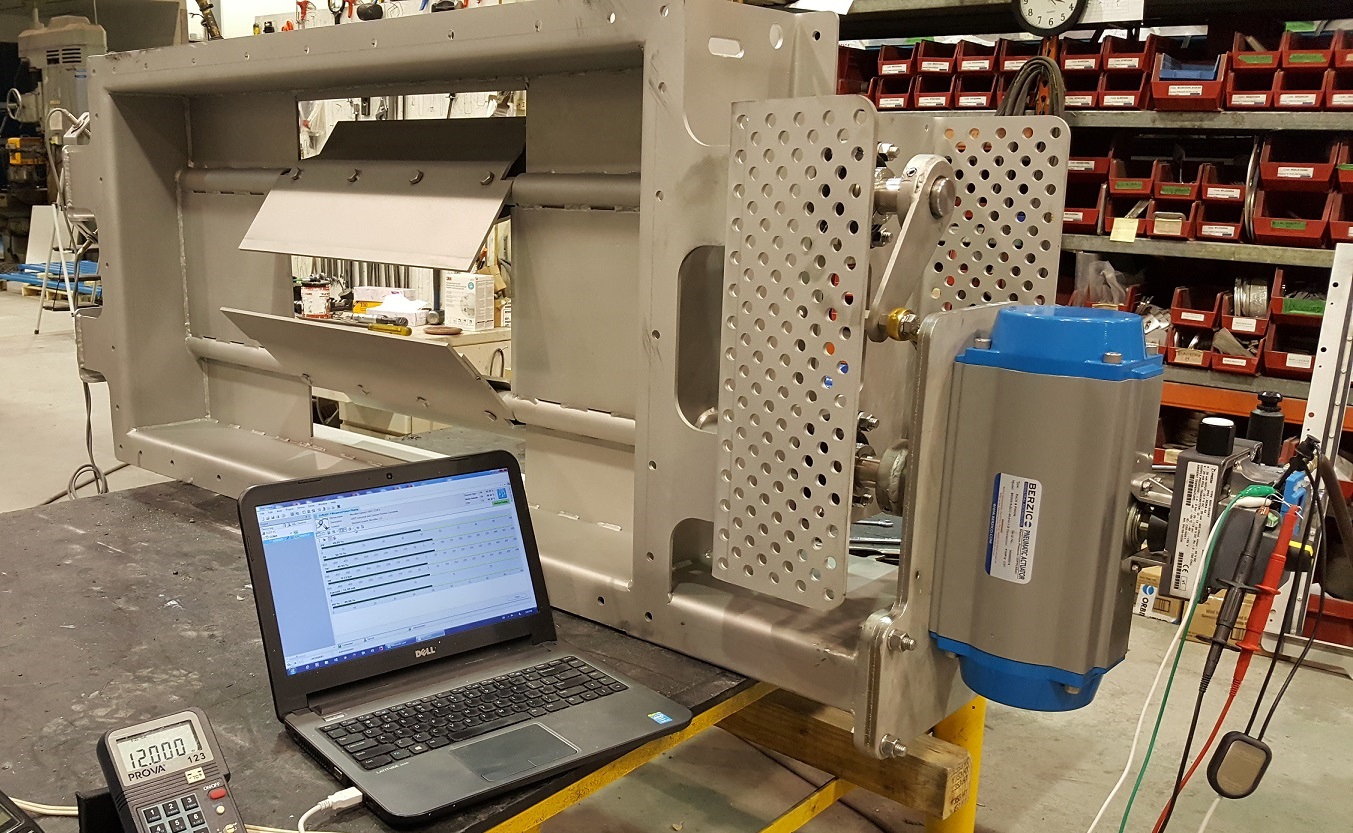

Our Canadian facility have recently designed and manufactured a specifically designed reduced orifice damper that will modulate flow through a 22”x 22” orifice, in a 48”x 24” duct at a Paper & Pulp Plant in the USA.

Some i ndustrial processes create conditions in ducting layouts where it is difficult to accurately modulate the flow . If a “modulating damper” blade moves from minimum to maximum of flow requirements with only few degrees rotation, resolution is dissatisfactory. Conversley, if a “modulating damper” blade makes 60 degree rotation and pressure changes are barely detectable, effective drag might not be enough. Finally, if a “modulating damper” just cracks open and the flow is already near allowable maximum, that is just an on/off damper with very expensive actuator controls, therefore, the best solution is a custom designed reduced orifice modulating damper.

ndustrial processes create conditions in ducting layouts where it is difficult to accurately modulate the flow . If a “modulating damper” blade moves from minimum to maximum of flow requirements with only few degrees rotation, resolution is dissatisfactory. Conversley, if a “modulating damper” blade makes 60 degree rotation and pressure changes are barely detectable, effective drag might not be enough. Finally, if a “modulating damper” just cracks open and the flow is already near allowable maximum, that is just an on/off damper with very expensive actuator controls, therefore, the best solution is a custom designed reduced orifice modulating damper.

We can size a reduced orifice damper to given control range requirements, and our approach gives a solution that matches the best possible turn down ratio available, by using optimised angular resolution. This damper can be a very cost-effective control solution, especially for applications where the damper configuration doesn’t even require modification to the existing ducting.

Our engineered solutions are increasingly in demand as we are recognised as International damper experts. Our innovative designs come in many configurations, custom damper packages are designed to meet diverse process requirements.

Contact us today to get a damper specifically designed for your application, from our head office and manufacturing plant in the UK, subsidiaries in India, North America and Denmark, and through a network of agents and licensed manufacturers, we offer a wide range of quality damper products and custom packages to industry worldwide.